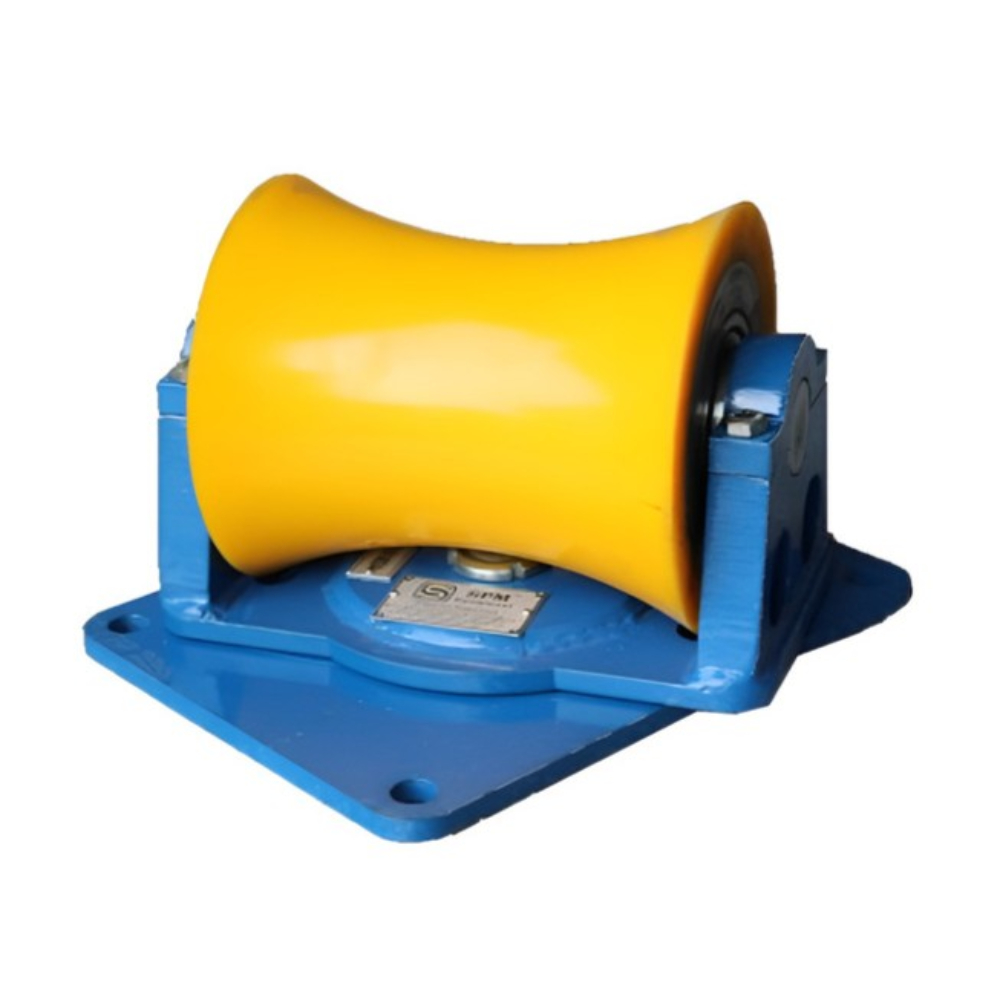

SPM Equipment, a leading Roller Cradle Manufacturer, offers advanced pipeline lowering solutions that provide both performance and protection. In Libya’s demanding oil and gas infrastructure sector, pipeline projects face challenging environmental conditions such as extreme heat, abrasive desert surfaces, and remote terrain. Under these conditions, the use of high-quality, precision-engineered pipeline handling tools is not optional but absolutely necessary. One such vital tool is the Roller Cradle. Designed for safety, precision, and efficiency, the Roller Cradle by SPM Equipment supports pipes during critical lowering-in, lifting, and transportation tasks. These tools not only help to prevent surface damage to the pipeline but also promote consistent movement across uneven terrains like those commonly found throughout Libya.

What Is a Roller Cradle?

A Roller Cradle is a specially developed piece of pipeline handling equipment designed to securely hold and support the weight of large pipes while they are being lowered into trenches or lifted onto trucks and carriers. The cradle typically comprises multiple heavy-duty polyurethane rollers mounted in a reinforced steel frame, forming a cradle-like shape that gently but firmly grips the pipe. The design of the Roller Cradle allows it to adjust dynamically to different pipe diameters, maintaining uniform contact to distribute pressure evenly. This dramatically reduces the likelihood of pipe coating damage, denting, or warping during transport and installation.

Key Features of SPM Equipment Roller Cradle

SPM Equipment has built its reputation on innovation, quality, and field-tested durability. Our Roller Cradles come with industry-leading features:

- Durable Construction: Made from high-strength, corrosion-resistant steel capable of withstanding tough field conditions.

- Heavy-Duty Rollers: Polyurethane-coated rollers reduce friction and safeguard pipe coatings from wear.

- Dynamic Pipe Fit: Cradle design accommodates multiple pipe sizes, offering flexibility on site.

- Modular Assembly: Easy to install, disassemble, and maintain.

- Enhanced Stability: Wide footprint and low center of gravity improve balance and safety.

Applications in Libya’s Harsh Terrain

Libya’s oil and gas installations often span miles of undeveloped land, rocky zones, and sandy plains. For projects in such regions, the Roller Cradle becomes a must-have equipment piece. It is perfectly suited for:

- Pipeline Construction and Laying

- Maintenance and Inspection Work

- Offshore and Onshore Installations

- Industrial Pipe Relocation Projects

When operating in areas like the Sirte Basin or near the Mediterranean coast, this tool delivers consistent results with minimal operational risk.

Benefits of Using SPM Equipment Roller Cradle

Using a Roller Cradle from SPM Equipment comes with multiple operational and economic advantages:

- Reduced Pipe Coating Damage: The soft, PU-coated rollers make contact without harming protective layers.

- Improved Workflow: Smooth rotation allows for continuous movement with less resistance.

- Increased Safety: Prevents slipping, jerking, or accidental drops during lowering or lifting.

- Labor Efficiency: Minimizes manual adjustments and accelerates handling operations.

- Versatile Usage: Compatible with different pipe sizes, weights, and coating types.

These benefits make it the perfect choice for contractors working under tight schedules and demanding terrain.

Design Engineering and Material Selection

Every Roller Cradle designed by SPM Equipment undergoes a strict quality control and design process:

- Material Quality: Only high-tensile steel and premium polyurethane are used.

- Weld Integrity: All joints are tested for strength and durability.

- Roller Geometry: Optimized for even load distribution and rotation.

- Surface Treatment: Anti-rust coatings extend the cradle’s lifespan in humid and saline environments.

This commitment to engineering quality translates to products that perform under extreme operational conditions.

Global Quality, Local Adaptability

SPM Equipment tailors each Roller Cradle to the specific environmental and operational needs of the project location. For Libya, this means:

- Wider bases for sand stability

- Heat-resistant materials for prolonged sun exposure

- Transport-friendly modularity for remote area access

As a Roller Cradle Manufacturer with a global export footprint, we understand regional challenges and build solutions accordingly.zz

Why Choose Us

SPM Equipment is a leading Roller Cradle Manufacturer committed to safety, durability, and customer satisfaction. Our Roller Cradles are built for performance under pressure, with careful consideration for the environmental and operational needs of our clients. We bring decades of experience in pipeline handling innovation and support customers across 30+ countries. With customized solutions, rapid delivery, and unmatched after-sales service, SPM Equipment is the trusted name in pipeline handling systems.

Conclusion

As Libya continues to expand its oil and gas infrastructure, the need for reliable and advanced pipe handling equipment grows exponentially. The Roller Cradle from SPM Equipment offers a combination of safety, efficiency, and rugged durability, especially crucial in the harsh terrains of Libya. Whether working in arid deserts or coastal basins, contractors can rely on our products to maintain pipeline integrity and project timelines.

For more details on our Roller Cradle or expert assistance for pipeline lowering solutions in Libya, call us at +91 9574770022 or mail us at: spmequipment@gmail.com. Our team is ready to assist you in building safer, smarter pipeline systems.